“As R&D we support MP3 delivering new products and solutions for ventilation and fire protection systems, looking into market needs.”

MP3 R&D designers

And prototypers work together with Sales team define the most appealing and innovative products. Then R&D focuses on developing the baseline concepts, keeping performance, quality and cost effectiveness as a target to accomplish.

Daily quality controls following FPC plan are also performed including mandatory tests for CE and NF marking:

Blade tightness controls according to EN1366-2 and Annex E of EN15650.

Proper operational functionality according to Annex E of EN15650.

Complete cycling tests according to Annex C and E of EN15650.

In addition to mandatory controls

Required by CE and NF marking, MP3 R&D laboratory is equipped to perform:

Casing leakage controls according to EN1751.

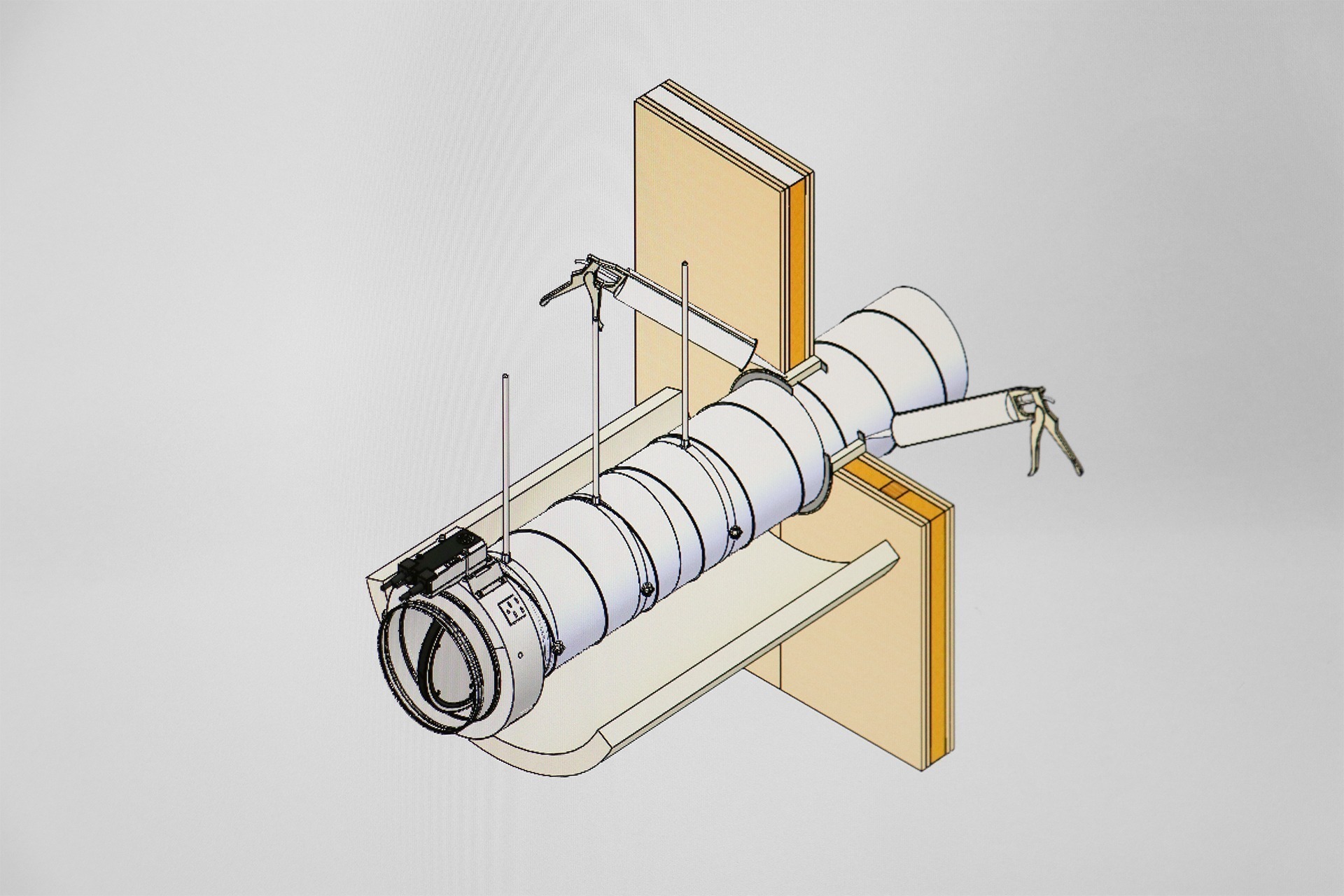

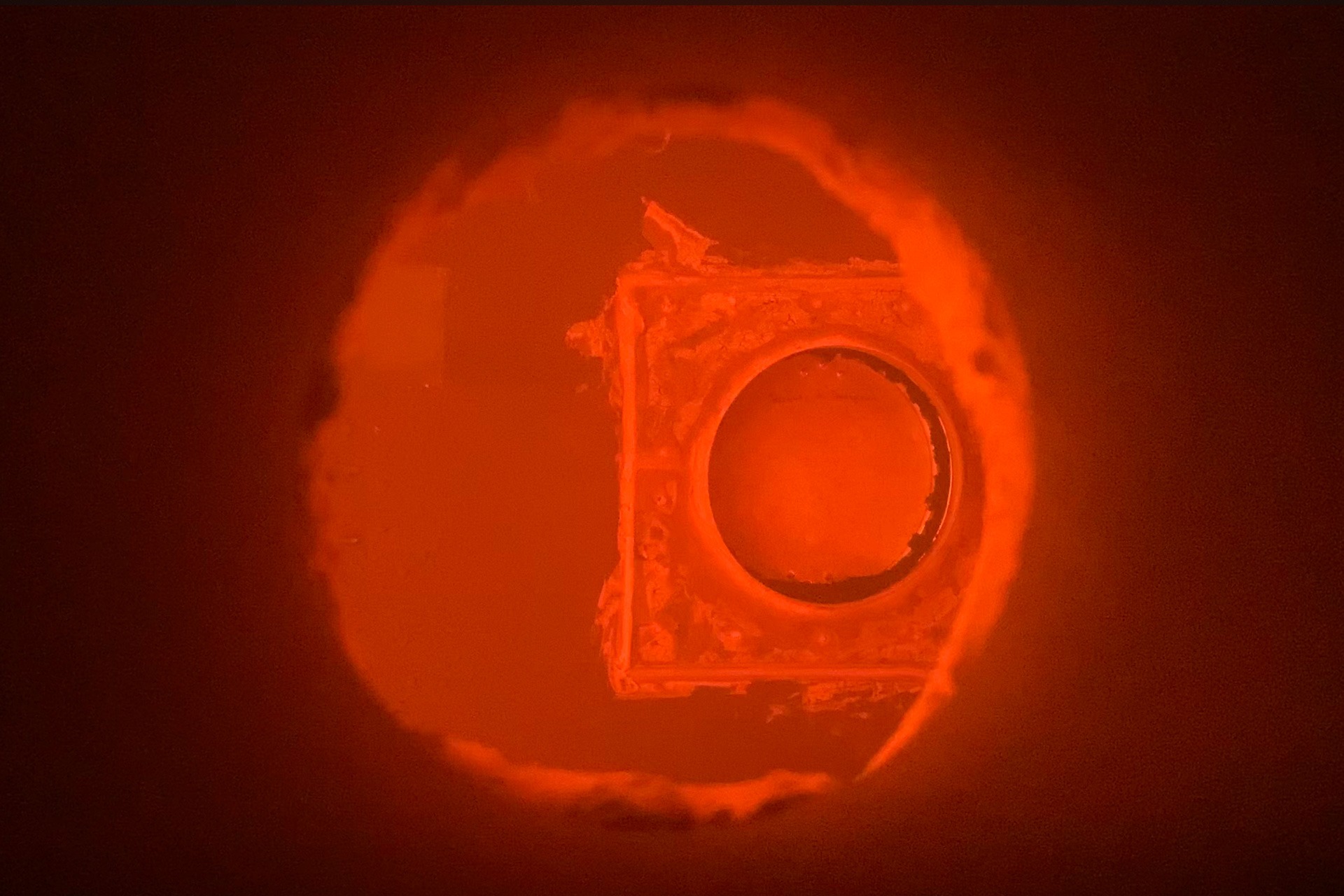

Complete fire tests of fire dampers installed into and remote from construction support according to EN1366-2 for research and control purposes.

R&D team is currently composed by 7 people:

2 senior prototypers.

1 R&D laboratory expert.

2 designers 3D.

1 fire and smoke specialist member of CEN work group involved in the preparation of technical Standards at national and internationa level.

1 coordinator.

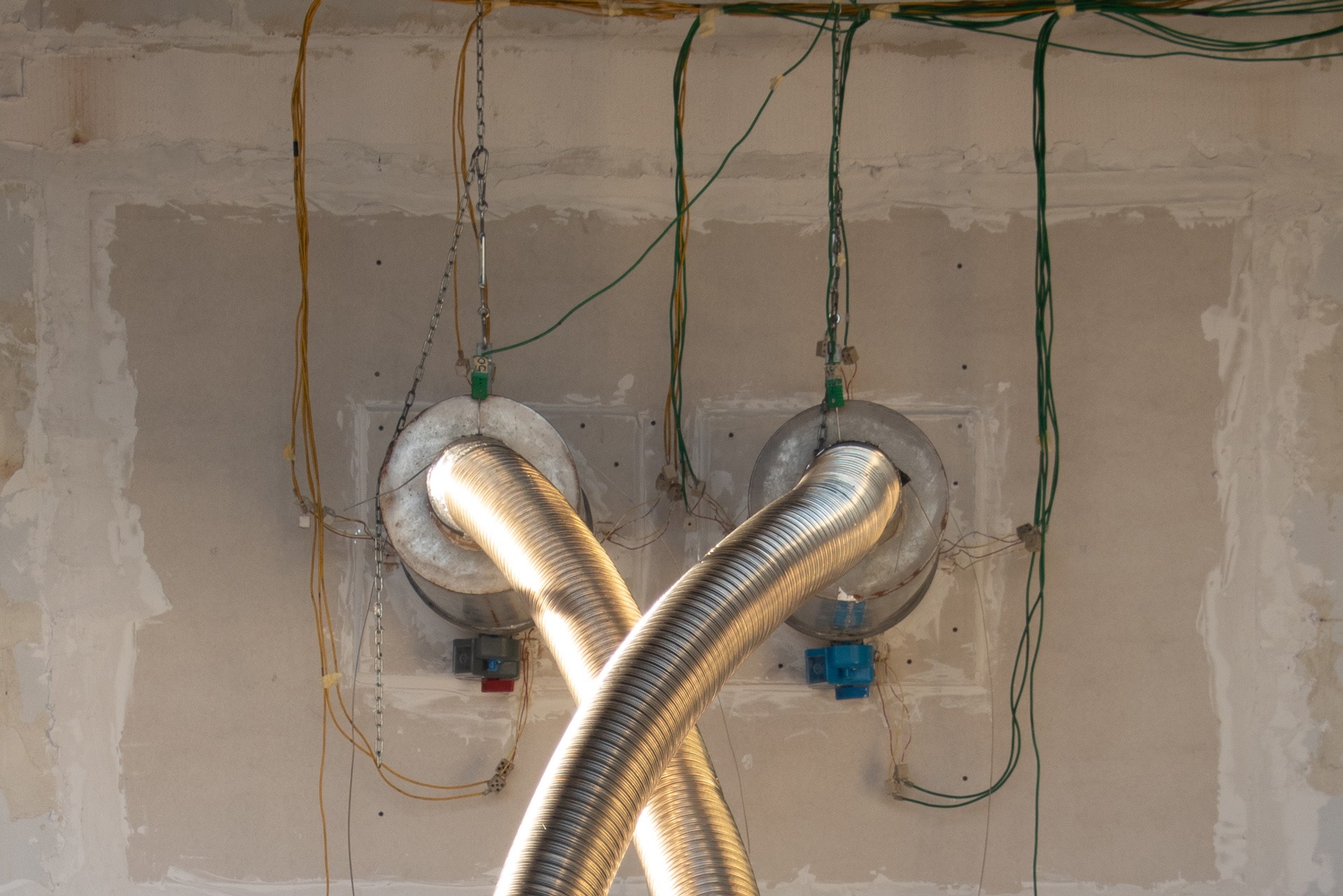

R&D Lab area is

Close to fire damper production, it is about 200 square meters wide and includes:

Electronic boxes for operational durability cycle tests: 16 outputs for:

closure device that can be trigged remotely but which is not able to re-open the damper without intentional intervention

general purpose actuator

modulating actuator

To accomplish Annex C

Of EN15650 cycling tests up to 20.000 cycles and more (stress tests).

Electronic boxes on line to accomplish EN 15650 daily testing.

Ventilation overpressure and underpressure system up to +/- 2000Pa (with possibility to extend the pressure values for special applications) capable to perform blade leakage tests according to EN1366-2, and casing / blade leakage tests according to EN1751.

Furnace to perform fire tests according to EN1366-2 in combination with ventilation system, with possibility to test different kind of construction supports up to 3500x3500mm.